- Benchtop High Speed Centrifuge

- Floor high speed centrifuge

- High speed refrigerated centrifuge

- Tabletop Low Speed Centrifuge

- Low speed refrigerated centrifuge

- Free-standing Low Speed Centrifuge

- Laboratory centrifuges

- Medical centrifuge

- Automatic decapping centrifuge

- Petroleum centrifuge

- Large capacity centrifuge

- Hematology Centrifuge

- PRP centrifuge

- Refrigerated Centrifuge

- Blood Bank Centrifuge

- Mini centrifuge

- Special centrifuge

- Centrifuge rotors

- Electronic Balance

- Vacuum Centrifugal Concentrator

- Moisture Analyzer

Medical centrifuge is a special equipment for rapid separation, concentration and purification of mixed substances with different precipitation coefficient by means of centrifugal force generated by high-speed rotation. It is widely used in medical and health care, blood stations, pharmaceutical factories, biomedical engineering, animal and plant research and other fields. However, there is no suitable technical means and calibration method in the direction of measurement and detection so far. Therefore, this paper proposes the research on the calibration method of medical centrifuge, which will play a huge role in promoting the development of medical centrifuge technology in the field of measurement.1, an overview of the

Medical centrifuge is a device that produces constant acceleration. It is widely used in the fields of medicine, biology and pharmacology. It is used to separate particles suspended in solution and separate two kinds of liquid with different densities that are not mutually soluble. It usually consists of a station body, control system, test parameter measurement and display system and its auxiliary equipment. According to the structure of the platform, it can be divided into two types: rotary plate type and rotary arm type.

2. Measurement characteristics

(1) Speed indicating error: the relative error of high-speed centrifuge speed is not more than ±1%, and the relative error of low-speed centrifuge speed is not more than ±2.5%.

(2) Speed stability: no more than ±1%.

(3) Noise of the whole machine :(A weight) should not be greater than 90dB.

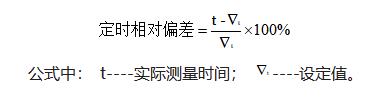

(4) Relative deviation of timing: the relative deviation of digital timing device should not be more than ±1%; The relative deviation of mechanical timer should not be more than ±5%.

(5) speed up and down time: centrifuge speed up time should be less than 10s, speed down should be less than 10s.

3. Calibration conditions

3.1 Environmental conditions

(1) Temperature :(10 ~ 40) ℃;

(2) Relative humidity :(30 ~ 85) %;

(3) Voltage range: 10% of the rated voltage;

(4) There should be no corrosive gas or liquid around the centrifuge environment; No strong electromagnetic interference; No vibration interference.

3.2 Calibration standard and other equipment

The serial number

Device name

Measuring range and technical requirements

1

Digital tachometer

Measuring range :(0 ~ 99999) RPM; 0.1 on the Richter scale

2

Electronic stopwatch

Measuring range :(0 ~ 3600) s; The index value of 0.01 s

3

Sound level meter

Measurement range :(40 ~ 100) dB (A); Type Ⅱ (weighting A)

Calibration equipment technical requirements and other equipment list

4. Calibration items and methods

4.1 appearance

(1) The centrifuge shall have a nameplate indicating the model, specification, manufacturer, license mark and number of manufacturing measuring instruments, factory number and date, etc.

(2) The actual parts of centrifuge control and measurement should be complete, and the connectors should be connected reliably; All switches, knobs and keys should function normally, operate flexibly and reliably, and should be clearly explained by words or symbols; Display part, the character should be clear and complete

4.2 Speed indicating error

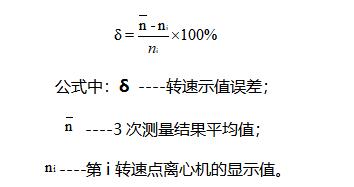

When the centrifuge is under no load, 3 speed set points should be selected evenly within the maximum speed range of the centrifuge and measured for 3 times each. The indicated value of the centrifuge speed and the indicated value of the tachometer used for calibration should be recorded. The error of the indicated value of the speed should be calculated according to the formula and comply with the provisions of 4.1.

4.3 Speed stability

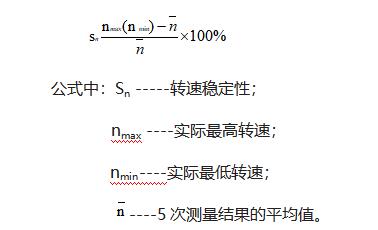

The centrifuge is no load, adjust the centrifuge to the maximum speed, and measure the speed every 2min with a 0.1 tachometer for 5 times in total after the speed is stable. Calculate the average value, and then use the formula to calculate the stability of the speed. Take the maximum or minimum value, which should conform to the provisions of 4.2.

4.4 Noise of the machine

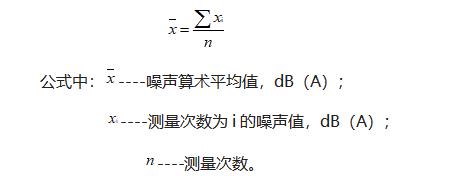

(1) Centrifuge no load, the centrifuge speed is adjusted to the maximum to ensure its normal work, in the distance from the front of the centrifuge 1m, with the sound level meter A weight measurement network for 5 times. The results shall meet 4.3.

(2) Stop the centrifuge and measure the background noise at the same position. When the background noise is more than 10dB lower than the measured centrifuge noise value (A weight), the measured value will not be corrected. In the case of 4dB ~ 10dB, the correction shall be made according to the following table; The measured value is invalid below 4dB.

The difference between noise value and background noise

4

5

6

7

8

9

10

Revised K.

2.2

1.7

1.3

1.0

0.8

0.6

0.4

Background noise correction table

Note 1 K represents the value to be subtracted from this measurement.

Note 2: Background noise should be corrected for quality arbitration.

4.5 Relative deviation of timing

When the electronic stopwatch is used to set the set value for 5min and 10min, the relative deviation between the measured time value and the set value should comply with the provisions of 4.4.

4.6 Speed rise and fall time

(1) Adjust the centrifuge to the maximum speed and prepare the timing with an electronic stopwatch.

(2) Start the centrifuge and measure the time required for the turning head to rise from 0 to the highest speed, namely, the speed rise time. When the rotating head of the centrifuge is at the highest rotating speed and keeps the rotating speed stable, press the stop button to measure the time required for the rotating head to drop from the highest rotating speed to 0, namely, the deceleration time. The calibration results shall conform to 4.5.

Hunan hussey

Hunan Hexi Instrument Equipment Co., Ltd. was registered and established in Xiangjiang New District in 2007. After more than 10 years of development, it has become a professional high-tech company with independent intellectual property rights, independent brand and independent innovation ability, which is specialized in research and development, production and sales of laboratory instruments and equipment, and a drafting unit of national standard of centrifuges.

The company mainly produces high-speed refrigerated centrifuge, super-large capacity refrigerated centrifuge, low-speed refrigerated centrifuge, normal temperature centrifuge, crude oil moisture determination centrifuge, vacuum centrifuge concentrator, 3H series intelligent centrifuge and latex moisture rapid tester, And in the same industry took the lead through ISO13485 medical device quality management system certification, ISO9001:2008 quality management system certification and CE certification.

The company's products are widely used in military industry, scientific research institutes, colleges and universities, central blood stations, hospitals, biological products, pharmaceuticals, biochemical testing, agricultural science, environmental protection and petrochemical, food and other production and research fields. Hexi Instruments has successively set up direct offices and after-sales service centers in Beijing, Guangzhou, Nanjing, Shenyang, Harbin, Xi 'an, Chongqing, Jinan, Kunming, Wuhan, Nanchang, Lanzhou, Changsha and other places.

- PREVIOUS:Laboratory centrifuge is a commonly used equipment for cell culture

- NEXT:From the editor, what do you know about vacuum centrifuge concentrators?